How To Make A Nut And Bolt Pipe

1 / 20

Utilize an Impact Driver When You lot Tin can

An impact driver and a set of high-end hex-shaft nut drivers are all you need to loosen small nuts and bolts. For larger basics and bolts, y'all'll need an bear on gun and a set of six-point, bear on-rated (black finish) sockets. Ordinary chrome sockets tin't handle impact work and may cleft or shatter under the stress. And because affect-rated sockets accept half-dozen points instead of 12, they're less likely to circular over bolt and nut heads.

2 / 20

Stuck Fasteners Can Seize with teeth Y'all

When it comes to causing pain, stuck fasteners can get the chore done. Right when you're giving a stuck commodities all your muscle, wrenches volition slip, bolt heads will snap off and your hands will go smashed confronting something precipitous. And so always clothing gloves and try to orient tool handles so your hands volition be clear if a tool slips.

Needless to say, pounding on stubborn fasteners with hammers, mallets and sledgehammers poses similar dangers. Never apply a regular hammer for metal-on-metal impact. Bits of the hardened metal tin break off and become embedded in your mankind. Safety glasses are a must, as well every bit hearing protection when you're running some of these very power noisy tools.

iii / xx

Lock on to Wrecked Heads

These pliers are best known past the brand name Vise-Grip. Whatever brand you lot have, they'll get you out of a jam when bolt and nut shoulders are rounded, or when screw slots or Phillips crosses are stripped out. Rounded jaws work best. Brand sure the jaws are seated on the flats of the nut/bolt or around the screw head, and tighten the handle as much every bit you lot possibly can before turning the fastener.

4 / twenty

Pound a Philharmonic Wrench

Box-end wrenches work improve than sockets on stuck heads considering they twist in the same plane as the head, rather than being offset past an inch or more than. That beginning means sockets are likelier to slip off heads and round over shoulders. Fit the closed finish of the wrench over the bolt head and try tugging in curt pulses, instead of a full-throttle pull. That'll help loosen rust-bonded surfaces. If that doesn't do it, tap on the wrench with a plastic, brass or wooden mallet. It's a good way to loosen the bones in your paw, too, so wear leather gloves and proceed your fingers well away from the touch on zone!

5 / 20

Piping Wrenches Aren't Just For Pipes

When you're dealing with really big stuck bolts, a pipe wrench might be your best selection, especially if you don't ain a giant set of wrenches or sockets. The long handle and aggressive jaw teeth will loosen the nigh stubborn bolts. Simply make sure y'all go the jaws tight against the shoulders. Piping wrenches are also a become-to tool when bolt shoulders have been rounded over.

half-dozen / 20

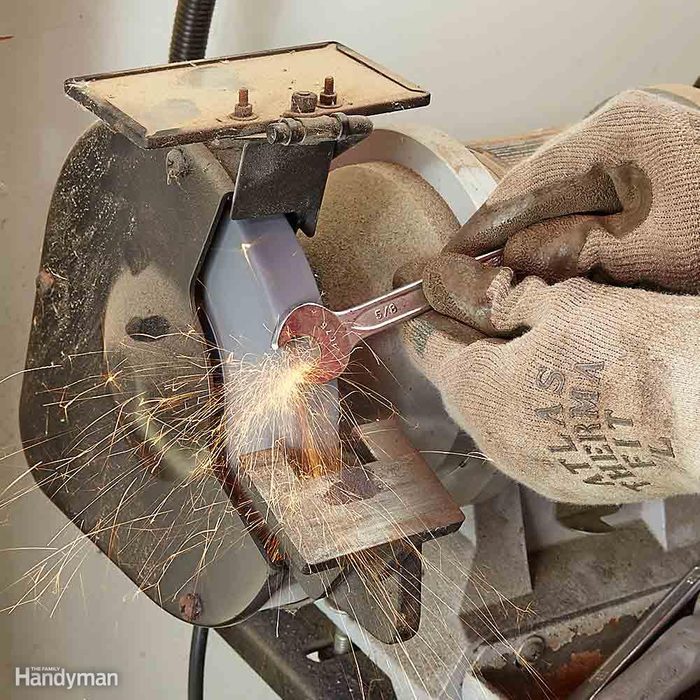

Sacrificing a Tool

It might seem sacrilegious to destroy a tool, only sometimes working in narrow or bars spaces makes it necessary. That's where your grinder comes in. Employ it to make wrenches thinner and screwdrivers skinnier and to add tapers to sockets so they fit into tight recesses. Just this technique comes with a warning. Grinding a tool compromises its integrity, so take actress precautions when using it (wear goggles and gloves). When you're done, toss the modified tool and get a new one—it'southward no longer prophylactic for apply on other jobs.

7 / xx

Oestrus is the Last Resort

Applying rut with a propane torch can expand a nut (or threaded opening) and loosen it. If you've tried everything and nevertheless can't free a bolt or nut, try heat. Simply first make sure the fastener is a good distance away from hoses, belts, gas tanks or annihilation else that might burn down up your car or kill yous in an explosion.

If the area is soaked with penetrant, spray it with nonflammable brake cleaner to remove it before you apply estrus. Keep a burn down extinguisher nearby. Once you've established that it'south safe, aim the flame at the bolt head or nut, not the surrounding metal. Rut for about 15 seconds, just don't go it reddish red. Then spray the bolt head with water to cool information technology chop-chop. Continue spraying until it no longer steams. The expansion/contraction cracks the rust, and then add together more rust penetrant, let information technology soak then add vibration by tapping information technology with a hammer or other tool. And so try to loosen it.

8 / 20

Whack Stuck Wheels

Sometimes rust will fuse wheels to the rotor, making information technology almost impossible to pull them off. If it happens to you when you're changing a tire or working on the brakes, loosen the lugs and prop a 2x10 confronting the tire, so pound abroad with the biggest sledgehammer you have. After a few swings, the wheel will popular correct off. Only if you wait until you have a apartment on the side of the road, yous won't have a sledge to free upwards a stuck wheel. So before you caput out on that road trip, possibly y'all should rotate those tires and make sure your wheels aren't stuck, specially if you have an older car with some rust.

9 / xx

Don't Mess Effectually—Cut It Off!

If you have a stuck nut/bolt that can exist replaced, don't beat yourself upwardly trying to unscrew the rusty one. Only cut off the stuck fasteners (or the parts around information technology if they're getting replaced) and buy new ones. Use a reciprocating saw with a hacksaw blade or, amend yet, a cutoff tool. (You lot tin become a cutoff tool for equally lilliputian every bit $30 at any domicile center or hardware store.) Then take the leftovers to the store to match them up with new ones.

10 / xx

Try an Impact Driver

When you lot need to tackle stuck slotted or Phillips screws, purchase a $15 hammer-way impact commuter. Apply rust penetrant and allow it to soak in. And so fit the right commuter chip in the end, and pound on the end with a ball-peen hammer. This shocks the fastener, cracks the rust and twists the bit, all at the same time. The hammer blow keeps the flake in the screw head, preventing farther damage to the slots.

11 / 20

Drill Out Rivets

Removing rivets is easier than you think. Just pick a drill bit that'due south a tad larger than the hole in the top of the rivet. Run the drill until the washer head is loose. Then poke the rest of the rivet out of the hole.

12 / twenty

Stuck Receiver Hitches

A ball mount that's been in the receiver hitch too long tin can rust in place. Here's the trick for freeing information technology up. Use an air chisel (about $xxx at any abode center or motorcar parts shop) and a special 1-in. hammer impact chisel. (We used the Grey Pneumatic 1' Bore Hammer, which is available at amazon.com.)

Subsequently saturating the receiver hitch with penetrant, hold the hammer alongside the receiver tube and pull the trigger. Permit the air chisel churr away at the hitch for a infinitesimal or then. And then repeat on the other side of the hitch and try sliding the shaft out. You may have to try a few times and give the hitch a few whacks with a maul, only eventually it'll come out. Before slipping it back in, coat the shaft with water-resistant marine grease so it won't get stuck once more.

13 / 20

Cheater Bar

Tool purists (and tool manufacturers) detest this tip considering they think it's both dangerous and an abuse of tools. Information technology is. But sometimes it's the only mode to go the task done, especially if y'all're removing big basics and bolts. Slide a metal pipage over the handle of a piping wrench, a combination wrench or a socket wrench. The pipe will add tremendous leverage. It may exist difficult on tools and might even pause them, only on the bright side, y'all'll most probable interruption the fastener loose and have fewer strained muscles and/or bruised duke.

14 / 20

Offset With a Rust Penetrant

Rust penetrants contain a solvent to dissolve rust, a lubricant to reduce friction and a surface tension reducer to go deep penetration. "Habitation brews" like Coca-Cola, kerosene and mineral spirits don't take all those ingredients. Neither does WD-twoscore (it's a swell lubricant, but information technology's non formulated equally a rust penetrant). Those products simply don't work also or as fast as actual rust penetrants (find penetrants like Liquid Wrench Penetrating Oil, Royal Purple Maxfilm and PB Blaster at dwelling centers and automobile parts stores). Soak all the bolts for at least 15 minutes before you attempt removal.

15 / 20

Then Hit It With a Hammer

If rust penetrant lone doesn't work, create micro cracks in the rust with blows from a hammer, or even better, an air chisel and hammer bit. Then employ more than rust penetrant and "reshock" the bolt head. Echo until you can turn the bolt.

sixteen / twenty

Try a Socket on Your Air Chisel

Utilise even more force to a rusted bolt with an air chisel socket adapter (No. PH1050 from snapon.com). Skid a wrench onto the adapter flats and crank away while you apply air hammer blows. The dual forces break the bolt loose.

17 / 20

Mangled Slot, Solution ane

If the slot of a roundhead screw or commodities is chewed upwards beyond hope of gripping information technology with a screwdriver, file two flat edges on it. Then turn the head with an adaptable wrench.

18 / 20

Mangled Slot, Solution 2

Use a hacksaw to cut a new slot at a right angle to the old one. For big screws, put two blades in your hacksaw, right side by side to each other, and cut a wider slot so you tin apply a big screwdriver. This is also a bully way to get a grip on the head of a stuck wagon bolt, which has no slot or flats.

19 / twenty

Split up a Nut

A nut splitter will crack any no-go nut without damaging the threads of the commodities or stem that information technology's screwed onto. Just sideslip the ring over the nut and plough the tooth into the nut until it breaks. Detect it at automobile parts stores or online.

twenty / 20

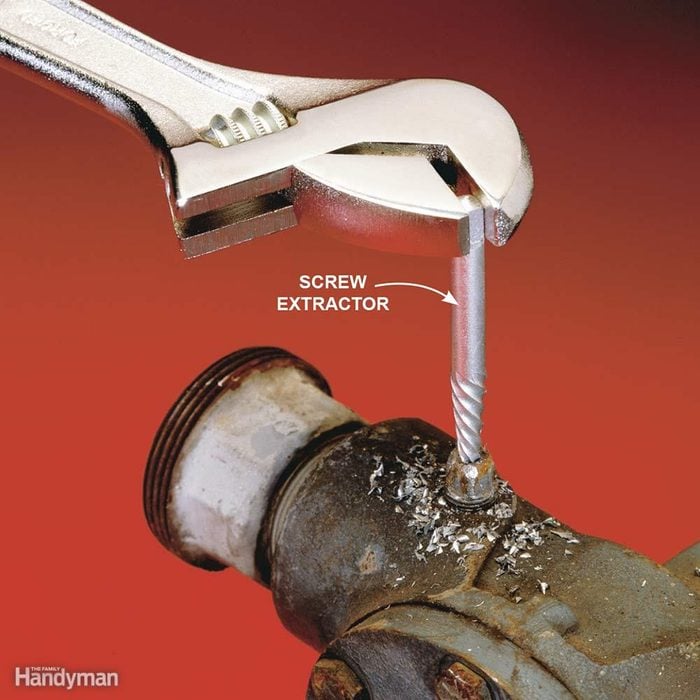

A Screw Extractor

A spiral extractor could save your day. It will grab just virtually any threaded fastener and remove information technology—even if the head has snapped off. It usually comes with a hardened drill bit to drill a hole in the center of your stubborn spiral or bolt. So you turn the extractor counterclockwise into the hole. Considering of its tapered shape and left-hand thread, the extractor volition jam in the hole and then brainstorm to plow out the screw. Yous can find extractors at hardware stores.

Originally Published: Oct 16, 2019

Source: https://www.familyhandyman.com/list/how-to-loosen-stuck-bolts/

Posted by: jimenezenwhat.blogspot.com

0 Response to "How To Make A Nut And Bolt Pipe"

Post a Comment